Injongo

Esi silumkiso sokhuseleko sigxininisa umngcipheko wokungaphumeleli kwemigca yokuhanjiswa kwempompo yekhonkrithi kuquka ukungaphumeleli kokufakwa kokuphela.

Amashishini alungelelanisa ukufakwa kwesiphelo kwimibhobho yokuhanjiswa kwekhonkrithi kunye nemibhobho kufuneka alandele kwaye abhale phantsi izenzo zobunjineli ezivakalayo kwaye anike ulwazi ngeendlela zokuhlola kubathengi.

Abanini bempompo zekhonkrithi kufuneka bafumane ulwazi kubanikezeli bemibhobho kunye nemibhobho kwiindlela zokuvelisa ezisetyenzisiweyo kunye neendlela ezifanelekileyo zokuhlola.

Imvelaphi

Kukho iziganeko eQueensland apho imigca yokuhambisa iye yasilela kwaye yatshiza ikhonkrithi phantsi koxinzelelo.

Ukusilela kubandakanya:

- ukusilela kombhobho wokuhanjiswa kwerabha

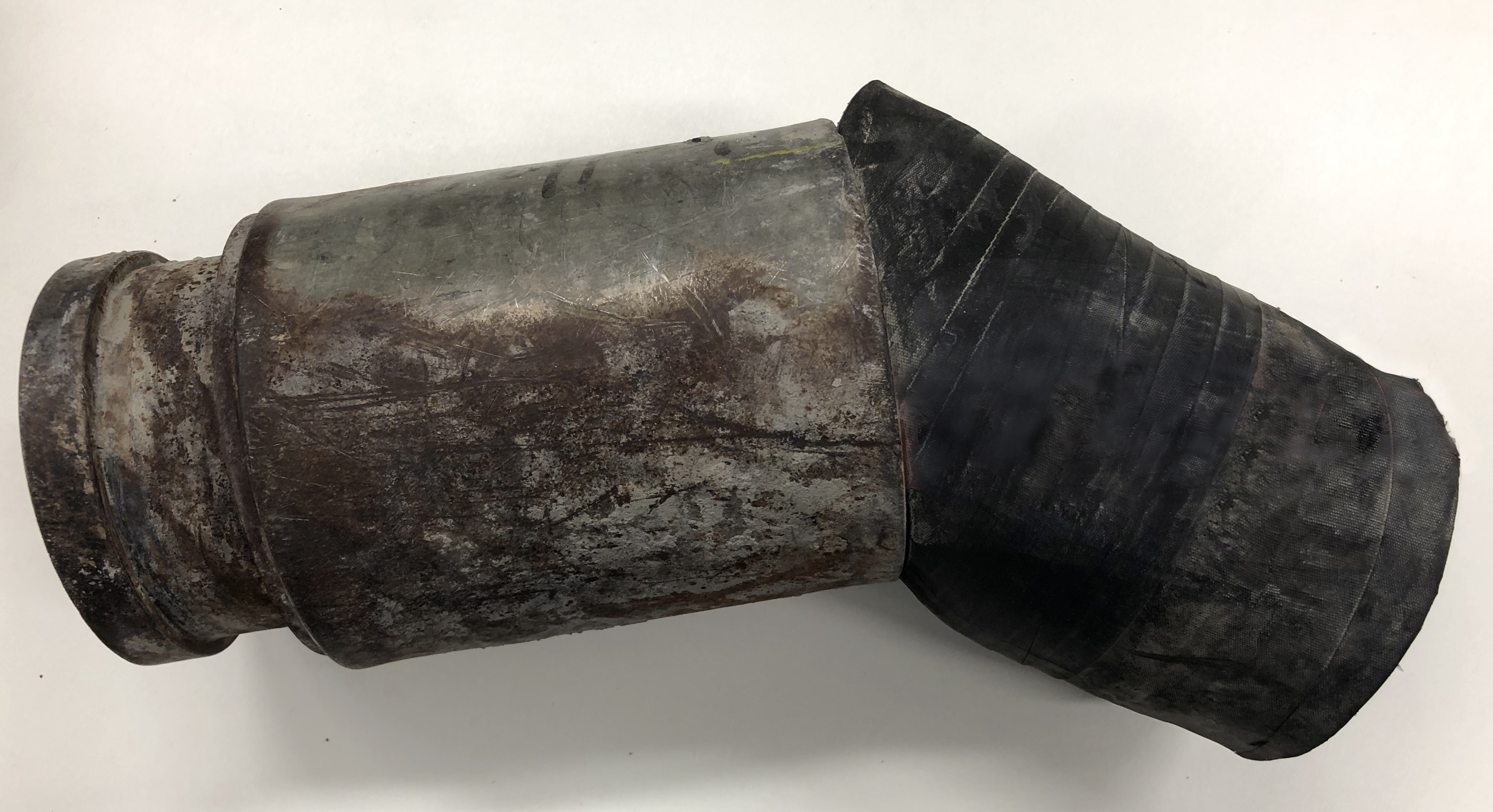

- Ukuqhekeka kwesiqu esidityanisiweyo kunye nesiphelo sokwaphuka (jonga uMfanekiso 1)

- isiphelo sokulinganisa siqala ukwahlula kumbhobho werabha (jonga iFoto 2) ngokutshiza ikhonkrithi ngaphandle komsantsa.

- ukuqhekeka kwe-flange kunye nokuqhekeka kwintsimbi ye-90-degree, i-6-intshi ukuya kwi-5-intshi yokuthoba i-bend, ebekwe kwi-hopper (jonga i-Photographs 3 kunye ne-4).

Uxinzelelo lokumpompa ikhonkrithi lunokuba ngaphezu kwe-85 bar, ngakumbi xa kuvela izithintelo.Zonke ezi ziganeko zinokubangela ukwenzakala okumandundu ukuba abasebenzi bebekufutshane nalapho kwenzeke khona ukusilela.Kwesinye isiganeko, ifestile yemoto yophuka kumgama omalunga neemitha ezili-15.

Indawo eqhekekileyo nengaphumeleliyo yesiqu sethumbu

Ukufakela isiphelo esijijekileyo esahlukileyo kumbhobho

I-flange ayiphumelelanga kwi-bend yensimbi yokunciphisa

Imiba enegalelo

Imibhobho kunye nofakelo lwesiphelo lunokusilela ngenxa yoku:

- ukulinganiswa koxinzelelo lwempompo yekhonkrithi edlula i-hose yerabha okanye izixhobo zokuphela

- ukunyamezela okungalunganga kumalungu angaphakathi nangaphandle okudibanisa

- inkqubo yokugrumba okanye yokukruqula ayihambelani nemigaqo yomenzi

- iinkcukacha ezingalunganga kwi-hose yerabha

- ukugqoka ngokugqithiseleyo-ingakumbi kwindawo yangaphakathi yokufakela ukusuka ekuhambeni kwekhonkrithi.

Iiflange kwimibhobho yentsimbi inokusilela ngenxa yoku:

- i-welding engalunganga ngenxa yee-electrode ezingalunganga, ukulungiswa okungalunganga, ukungabikho kokungena, okanye ezinye izitenxo zokuwelda

- iiflange kunye nemibhobho eyenziwe kwiintlobo zentsimbi enokuba nzima ukuyidibanisa

- Ukudityaniswa kakubi kweeflange kwimibhobho (okt iflange ayingeni kakuhle kwisiphelo sombhobho)

- ukuphathwa kakubi kweflange yombhobho (oko kukuthi, ukubhabhisa iflenge okanye umbhobho ngehamile xa umbhobho osecaleni kunye/okanye iqhoshana lombhobho lingalungelelaniswanga)

- izibophelelo zemibhobho ezingafakwanga kakuhle (umz. ubungakanani obungachanekanga, ukwakhiwa kwekhonkrithi).

Kufuneka isenzo

Abanini bempompo zekhonkrithi

Abanini bempompo zekhonkrithi kufuneka baqinisekise ukuba izinga loxinzelelo lwempompo yekhonkrithi alugqithisi lombhobho.Umzekelo, ukuba impompo ilinganiswe kwi-85 Bar yoxinzelelo lwekhonkrithi ngoko akwamkelekanga ukuba umbhobho wentsimbi utshintshwe ngombhobho werabha ngowona mgangatho uphezulu we-45 Bar.Abanini kufuneka kwakhona bathathe amanyathelo afanelekileyo okuqinisekisa ukuba iprogram yoqinisekiso lomgangatho iyalandelwa ngelixa ifakela i-end fittings ukwenzela ukuba ukungaphumeleli kokufakwa kokuphela kuthintelwe.Kulula ngokubanzi ukufumana isatifikethi kumthengisi wasekhaya xa kuthengwa izixhobo.

Ukuba umnini wempompo yekhonkrithi ungenisa amacandelo avela phesheya, kunokuba nzima ukufumana ulwazi oluthembekileyo kwinkqubo yokuvelisa.Oku kunjalo xa umthengisi waphesheya engaziwa okanye akukho phawu lomenzi.Abavelisi abanganyanisekanga nabo baye baziwa ngokukopa amagama abavelisi kunye neempawu zorhwebo, ngoko ke ukuphawulwa kweemveliso kukodwa akunakubonelela ngobungqina obaneleyo bokuba loo mveliso iyifanele injongo yayo.

Umnini wempompo yekhonkrithi ongenisa izixhobo ezivela phesheya kolwandle uthatha imisebenzi yomthengi ongaphandle phantsi kweUMthetho weMpilo noKhuseleko eMsebenzini ka-2011(WHS Act).Umrhwebi othenga kumazwe angaphandle kufuneka enze, okanye alungiselele ukuba uyenzile, naziphi na izibalo, uhlalutyo, uvavanyo, okanye uvavanyo lwezixhobo zokulawula umngcipheko wokhuseleko.

Ababoneleli bemibhobho kunye nemibhobho

Ababoneleli bemibhobho kunye nemibhobho enezifakelo zokugqibela kufuneka baqinisekise ukuba inkqubo yoqinisekiso lomgangatho iyalandelwa ngelixa kuhlonyelwa izifakelo zokugqibela kunye nokuba ulwazi kule nkqubo luyafumaneka kumthengi.

Ababoneleli kufuneka kwakhona banike imiyalelo ebhaliweyo kwiiparamitha zokusebenza zemveliso kunye neendlela zokuhlola eziza kusetyenziswa.

Ukuba umthengisi uqhoboshela izixhobo zokugqibela kwimibhobho okanye imibhobho, umthengisi uthatha imisebenzi yabavelisi phantsi koMthetho we-WHS ukongeza kuloo misebenzi yababoneleli.

Ukufaka izixhobo zokugqibela kwimibhobho

Izixhobo zokugqibela zifakwe kwi-hoses ye-rubber usebenzisa iindlela ezimbini, i-crimping kunye ne-swaging.Ngendlela ye-crimping, i-compressive forces isetyenziswe kwi-radially kwinxalenye yangaphandle (i-ferrule) yesiphelo esifanelekileyo kunye nesiqu sangaphakathi esifakwe ngaphakathi kwesiphelo se-hose.Ukufakwa kwesiphelo esikrunekileyo kunokuqondwa ngokucacileyo ngokuhambelana okucacileyo ngaphandle kwesilinganisi sesiphelo (jonga iFoto yesi-5).Ngendlela yokuguqula, ukugqiba ukugqiba kufakwe kwi-hose xa ukufakwa kwesiphelo kutyhalelwa ekupheleni kombhobho phantsi koxinzelelo lwe-hydraulic.Nangona kuya kubakho ukuphawulwa ekupheleni kokulungelelaniswa kwenkqubo yokwenziwa, ukufakwa kwesiphelo se-swaged akunanto ibonakalayo njengokufakwa kwesiphelo esikrunekileyo.Ifoto yesi-2 ngumzekelo wokufakwa kwesiphelo esijijekileyo esahlulwe ngokuyinxenye kumbhobho.

Nangona i-crimping kunye ne-swaging yahluke kakhulu, zombini iindlela zixhomekeke kakhulu ekusebenziseni amacandelo asemgangathweni okunyamezela okuchanekileyo kunye nokuqinisekisa inkqubo engqongqo yokuncamathisela ukufakwa kwesiphelo.

Abavelisi bombhobho baya kuqinisekisa kuphela ukuba ithumbu labo liyakwazi ukumelana noxinzelelo lwekhonkrithi oluchaziweyo xa iziphelo zemibhobho ekumgangatho ophezulu zifakelwe.Abanye abenzi bombhobho basebenza phantsi kwengcamango ye-aisibini esihambelanayoapho baya kuqinisekisa kuphela i-hose yabo yoxinzelelo oluphezulu, xa izixhobo zokugqibela ezivela kumvelisi othile zisebenzisa i-crimping eqinisekisiweyo okanye indlela yokuguqula isetyenziswe.

Xa udibanisa izixhobo zokugqibela kwimibhobho qinisekisa:

- ukuthotyelwa kwayo yonke imiqathango echazwe ngumbhobho kunye/okanye umenzi wokugqiba ukulinganisa

- i-hose material kunye nemilinganiselo ifanelekile ukupompa ikhonkrithi kunye nokulungelelaniswa kohlobo oluthile lokugqiba ukugqiba

- Ubungakanani beendawo zangaphandle kunye zangaphakathi zokufakela kufuneka zibe ngaphakathi konyamezelo oluchazwe ngumenzi wethumbu okanye umenzi wokulinganisa imilinganiselo yombhobho osetyenzisiweyo.

- indlela yokudibanisa ukuphela kokugqiba kufuneka ihambelane neenkcukacha zomenzi (ulwazi oluvela kumenzi we-hose lunokufuneka kwakhona).

Uvavanyo lwesiphelo esifanelekileyo yindlela enye yokunceda ukubonisa ingqibelelo yoqhagamshelo.Uvavanyo lobungqina bazo zonke izixhobo okanye uvavanyo olutshabalalisayo lweesampulu ziindlela ezinokusetyenziswa.Ukuba uvavanyo lobungqina luyenziwa, indlela yovavanyo kufuneka iqinisekise ukufakwa kunye nombhobho awonakaliswa.

Ukulandela ukuqhotyoshela ukufakwa kwesiphelo kwi-hose, ukufakwa kufuneka kumakishwe ngokusisigxina ngolwazi kwinombolo yebhetshi kunye nophawu lokuchongwa kwenkampani efakela isiphelo.Oku kuya kunceda ngokulandelelwa kunye nokuqinisekiswa kwenkqubo yendibano.Indlela yokumakisha akufanele ichaphazele kakubi ingqibelelo yendibano yombhobho.

Ukuba kukho amathandabuzo malunga nenqobo yokuvelisa okanye uvavanyo olunxulumene nokufakwa kwesiphelo, ingcebiso yomvelisi wesixhobo sokuqala (i-OEM) kufuneka ifunyanwe.Ukuba oku akufumaneki, kufuneka kufunyanwe ingcebiso yenjineli eqeqeshelwe ngokufanelekileyo.

Ulwazi olubhaliweyo malunga nendlela yokuncamathisela isiphelo kufuneka sigcinwe lishishini elincamathela isiphelo kwaye kufuneka lifumaneke xa liceliwe.

I-Welding flanges kwipayipi yentsimbi

I-Welding flanges kwi-piping yentsimbi esetyenziselwa ukupompa ikhonkrithi ngumba onzima kwaye ufuna amanqanaba aphezulu okufakwa kwezobugcisa kunye nobuchule bokuqinisekisa ukuba inkqubo ye-welding iya kubangela imveliso esemgangathweni.

Oku kulandelayo kufuneka kuqinisekiswe:

- Kuphela umbhobho olungiselelwe ngokukodwa ukumpompa ikhonkrithi kufuneka usetyenziswe.Ngaphambi kwe-welding, kufuneka kubekho indlela ethembekileyo yokuqinisekisa ukuba umbhobho kunye neeflange luhlobo lwangempela oluyalelweyo.

- Inkcazo ye-weld kufuneka ihambelane nombhobho kunye neempawu zezinto ze-flange kunye neenkcukacha zoxinzelelo lombhobho odibeneyo.Ulwazi kufuneka lufunyenwe kumenzi wombhobho kulo mbandela.

- I-Welding kufuneka ihambelane nenkqubo ye-weld eneenkcukacha ezibandakanya ukhetho lwe-electrode, imiyalelo yokufudumeza kwangaphambili (apho kuyimfuneko) kunye nokusetyenziswa kwendlela yokudibanisa ekhuthazwa ngumenzi wombhobho.

- Ukuqhuba uvavanyo olonakalisayo kwisampulu yokuvavanya ukuqinisekisa indlela ye-welding ilungele injongo.

Ukuhlolwa kwemibhobho nemibhobho

Abanini kunye nabaqhubi bezixhobo zokupompa ikhonkrithi kufuneka baqinisekise ukuba ukuhlolwa okuqhubekayo kwemibhobho kunye ne-hoses kwenziwa.Iindlela zokuhlola kunye nezithuba zokulinganisa ubukhulu bombhobho zichazwe kwiIKhowudi yokuSetyenziswa yeConcrete yokumpompa ngo-2019(PDF, 1.97 MB).Nangona kunjalo, ukongeza, inkqubo yokuhlola kufuneka isetyenziswe ekupheleni kokufakwa kwimibhobho yerubha kunye neeflange kwiipayipi zetsimbi.

Ukuhlolwa kwemibhobho

Ulwazi olubhaliweyo malunga nokuhlolwa kwemibhobho (oko kukuthi ukusuka kwi-OEM), kufuneka ibonelelwe lishishini elihambelana nesiphelo kwaye oku kufuneka kudluliselwe ngumthengisi we-hose kumsebenzisi wokugqibela.

Inkqubo yokuhlola kufuneka ibandakanye ukuhlolwa ngaphambi kokusetyenziswa kunye nokuhlolwa kwamaxesha athile kunye nekhefu elisekelwe kubuninzi bokusetyenziswa kunye nendawo yokusebenza.

Inkqubo yokuhlola kufuneka ibandakanye:

- Uhlolo lwangaphakathi olunamanqanaba okukhanya okwaneleyo okujonga iityhubhu zetyhubhu zinobukhulu obufanelekileyo, akukho ilaphu lelaphu okanye intsimbi yokuqinisa eveziweyo, akukho zithintelo, ukukrazula, ukusikeka okanye iinyembezi zetyhubhu yelayini, kwaye akukho ziqendu zidilikileyo zetyhubhu yangaphakathi. okanye ithumbu

- Ukuhlolwa kwangaphandle ukukhangela umonakalo we-inshorensi kuquka ukusikeka, iinyembezi, i-abrasion eveza izinto eziqinisayo, ukuhlaselwa kweekhemikhali, i-kinks okanye iindawo ezidilikileyo, iindawo ezithambileyo, ukuqhekeka okanye imozulu.

- Ukuhlolwa kwezixhobo zokugqibela zokugqoka ngokugqithiseleyo kunye nokunciphisa ubuninzi bodonga

- ukuhlolwa okubonakalayo kokufakwa kokuphela kweentanda.Ukuba kukho nawaphi na amathandabuzo okanye kukho imbali yokuqhekeka, uviwo olungonakalisi lungafuneka

- ukujonga izixhobo zokugqibela zicocekile kwaye azityibiliki kumbhobho ngenxa yobudala okanye kwimithwalo yokutsala ngoomatshini.

Ukuhlola iiflange ezidityanisiweyo kumbhobho wentsimbi

Ukongeza kuvavanyo lobunzima bombhobho wensimbi (ocaciswe kwiKhowudi yokusebenza) kunye nokujonga umbhobho womonakalo, kubalulekile ukujonga iiflange kumbhobho wokupompa ikhonkrithi.

Inkqubo yokuhlola kufuneka ibandakanye ukuhlolwa:

- iiweld zokuqhekeka, i-weld elahlekileyo, i-weld undercut kunye ne-weld consistency

- iiflange ukujonga ukuba azikhubazeki kwaye azinamanqaku ehamile

- umbhobho uphela ngaphakathi ngenxa yokuguga ngokungalingani kunye nokuqhekeka

- iiflange zokuqinisekisa ukuba zikhululekile kulwakhiwo lwekhonkrithi kunye nezinye izinto zangaphandle.

Ixesha lokuposa: Aug-07-2021